Process diagram

Sample Answer 1

The diagrams show how glass containers, such as bottles, are produced and recycled.

The first flow diagram illustrates the process of glass container production, and the second diagram shows steps in the process of recycling used glass.

We can see that glass is made using three main raw materials, and that the manufacturing process consists of four distinct stages. It requires five steps to turn used glass into new glass products.

At the first stage in the production of glass, sand, soda ash, limestone and other chemicals are mixed together. Next, this mixture is heated in a glass furnace at approximately 1500 °C to produce molten glass. The molten glass can then be shaped, by blowing (通过吹制), to create the end products, namely glass containers.

Glass recycling begins with the collection of used glass products. The collected glass is sorted according to its colour, and then washed in order to remove any impurities (n. 杂质;不纯;不洁). At the fourth stage of recycling, the glass is crushed (adj. 压碎的,倒碎的) and melted (adj. 融化的;溶解的), and the resulting molten glass can finally be moulded (adj. 熔化的;炽热的;铸造的) to create new items.

Sample Answer 2

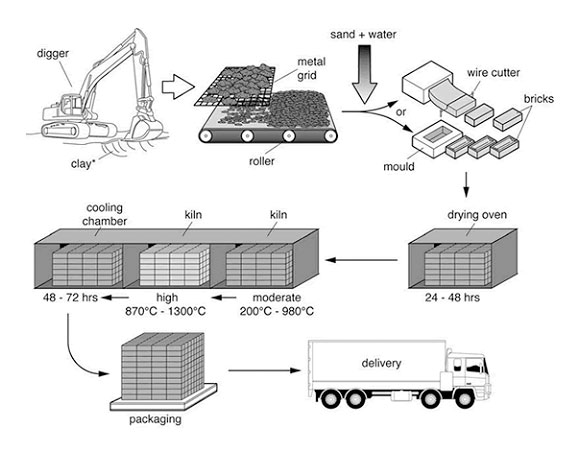

The Brick Manufacturing Process

The diagram explains the way in which bricks are made for the building industry. Overall, there are seven stages in the process, beginning with the digging up of clay and culminating in delivery.

To begin, the clay used to make the bricks is dug up from the ground by a large digger. This clay is then placed onto a metal grid, which is used to break up the clay into smaller pieces. A roller assists in this process.

Following this, sand and water are added to the clay, and this mixture is turned into bricks by either placing it into a mould or using a wire cutter. Next, these bricks are placed in an oven to dry for 24 – 48 hours.

In the subsequent stage, the bricks go through a heating and cooling process. They are heated in a kiln at a moderate and then a high temperature (ranging from 200c to 1300c), followed by a cooling process in a chamber for 2 – 3 days. Finally, the bricks are packed and delivered to their destinations.

Tips

- How many steps

- Where the process begins and ends

- Each step in the process